Problem Statement

Canada’s housing shortage continues to worsen, with estimates showing that the country needs 3.5 million more homes by 2030 to meet demand and improve affordability. Despite major government investment into prefabricated and modular housing to accelerate delivery and reduce costs, many solutions still rely on on-site assembly and customer coordination, adding expense, time, and complexity, especially in remote or off-grid locations.

Our client, Canadian Eco Prefab, approached us to develop a fully shippable, ready-to-use prefab cabin that could be delivered as a complete home. Not a kit, not a box of parts. Beyond logistics and affordability, the design needed to feel like a real home: spacious, human-centered, and livable, not a cramped, modular box. The goal was to create a space people actually want to live in, not just something that technically functions as housing.

We delivered a fully engineered solution with integrated architectural, structural, mechanical, electrical, and plumbing systems designed for CSA certification, scalable manufacturing, and province-wide shipping across Ontario. The result is a cost-effective, sustainable, fully built home that arrives ready for installation, requiring only foundation work and utility connections - combining manufacturability, transportability, and real human-first design in a single system.

Ready to Ship Fully Prefabricated Cabin for Ontario

Manufacturing and Assembly

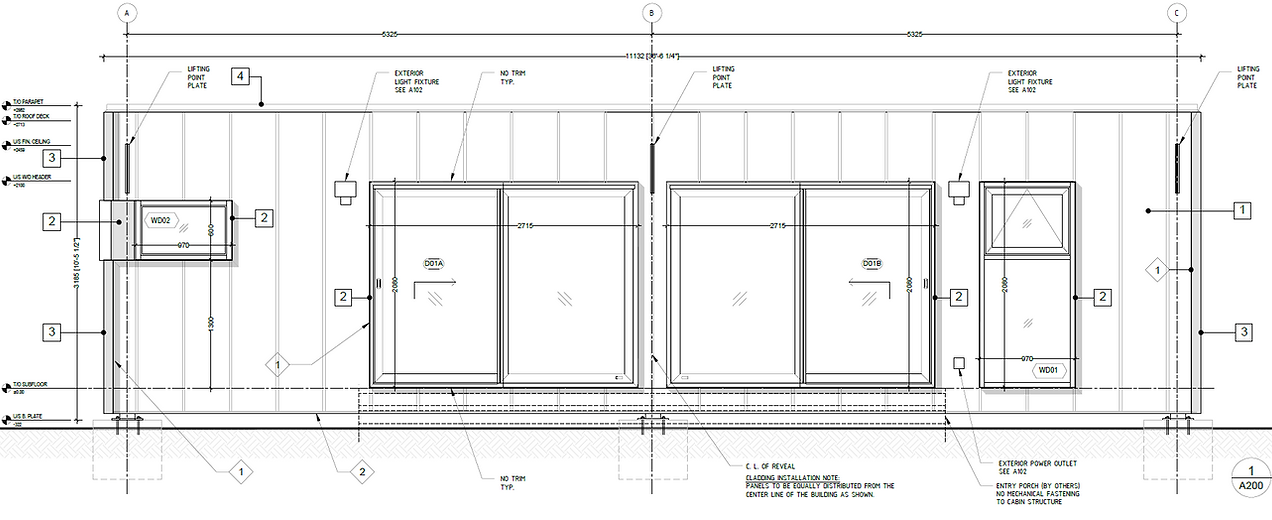

Since the prefab cabin had to be shipped in one piece in a low-buoy trailer for over 1,000 km all across Ontario, it had to be designed to sustain loads during the pick up phase, transportation phase, and the drop off phase, aside from the normal load conditions that a house would undergo (snow load, wind load, seismic, etc.). Due to this, it was evaluated that it could not be made with conventional means such as wood.

Instead, each unit is manufactured using a structured factory production sequence, beginning with a welded HSS steel chassis and progressing through light-gauge steel structural framing, floor systems, roof systems, and full building envelope integration. Exterior sheathing, weather barriers, insulation systems, vapor control layers, and air sealing are installed in a controlled environment to ensure performance consistency and regulatory compliance.

Mechanical, electrical, and plumbing systems are fully integrated at the factory level, followed by interior closures, exterior cladding, and full interior finishes. All structural, envelope, and building systems are coordinated to support CSA certification, scalable manufacturing, and transport as a single complete unit.

Final systems testing, quality assurance, and transport preparation ensure each cabin is delivered as a fully functional, site-ready structure, minimizing on-site labor and enabling rapid deployment across Ontario and future provincial markets.